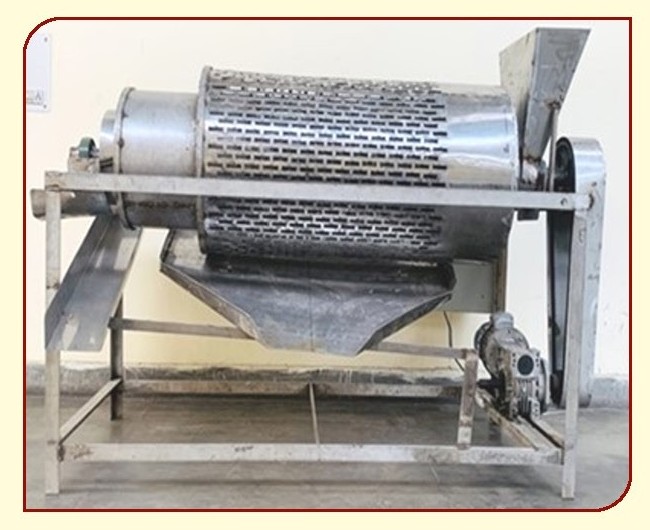

Popped Makhana Grading Machine

About the Technology

As per the market demand, the popped makhana is grading in 3 sizes (> 18mm,15mmand 13-15mm). Separation of all these sizes is done by sieving through round hole screens of different sizes. These sieves are usually made of tin or mild steel, which is not desirable. The used round perforations is not able to separate flattened makhana and hence manual picking is required. This adds to the labour cost as well as does not ensure hygiene of the product. The ICAR-CIPHET developed machine grades the popped makhana effectively on the basis of its size. It is a cost effective system of smaller size with low with low energy and labour requirement with high throughout capacity. The machine separates the un-popped material and grades the popped makhana in 3 sizes. The flattened makhana is also separated effectively, which eliminates the need of manual operation completely. The machine is simple in operation and fabrication with SS304 ensures hygiene and quality of the product.

Salient Features

-

- Simple and compact grading machine for grading of popped makhana in different sizes (12-15mm, 15-1Smm and >18mm diameters) and separate flattened and un-popped makhana.

- The machine is operated by 1 hp electric motor and require 2 unskilled labour.

- Makhana contacting surfaces are made of high-grade stainless steel, ensuring good product quality and hygiene.

- Capacity of the machine is 150kg popped makhana per hour.

Stakeholders

- Food Processing Equipment Manufacturers

- Makhana Processing Industry